PCB silkscreen designġ.The distance between the silkscreen and the pad The silkscreen needs to have a distance of 3-6Mil from the solder mask window pad, because it will have deviations during production.Ģ. If the silkscreen design is too small, it will cause difficulty in screen printing, but if it is too large, the silkscreen will overlap each other, making it difficult to distinguish, etc. For example, the silkscreens cover the SMD pad, which brings inconvenience to the PCB continuity test and component soldering. Water wont have an effect on it.Engineers will consider the power integrity and signal integrity of the product during the layout process, but the manufacturability of silkscreen is easily overlooked. You can use a heat gun to flash the ink, then let it sit for an hour. Not being able to get it to temperature, you will want to use plastisol for the stencil. If you use water based on the silks, for the stencil, You may melt your screen while trying to cure it. If you need to get plastisol into a CIS, I'll help. If you want to give it a try, I can give you any info you may have trouble finding. You can check the craft forums for "inkjet stenciling" a few people use the ink to fabric in negative to make a stencil. It makes no sense, if you have a DTG printer to print a screen because you dont need one. After curing the inks on the screen, I masked the outline with tape, then printed from that. In the early days, before I made my own films, I would use a screen to make another screen in reverse. If you are doing masking, you will only need to purchase one color of DTG ink. If you want to give it a try, get a used inkjet printer and get some refillable(empty) heads/cartridge or preferably a CIS (continuous inking system). If you need any help, I screenprint regularly. If you want a good place to start the research, check out You will have to do some searching to find links. After a few sec in a toasteroven to set the ink, and done. If you do a bit of pcb making, you can convert your ink supply to DTG ink (Direct to Garment) This allows your inkjet to "silkscreen" directly to the pcb. If you have an inkjet printer than can do straight-through printing of something as thick as a pcb, you can have a much easier time. Plastisol inks can be used with good results. If you decide to try direct to silk printing, you must not use water based inks to screen print with, you will just smear inkjet ink. However the price for inkjet ink is exponentially higher than photoresist emulsion and water. Instead of emulsion, you can print, directly to the screen, (using 220 mesh or higher) allowing you to skip the emulsion. The mask should be removed while the ink is wet, and that isnt easy without a physically removable mask. As for silkscreening, You can use a mask method, but removing the mask without removing the print is very difficult. There is a yellow inkjet ink that has a high acid resistance, used for the etching mask. The trick is to rub the ink into the image before pressing to the PCB and squeegeing. But, if you have a craft store near by, you can get a bottle of silk screening ink. You can use thinned latex paint for an ink. Then either spray out where the image is, or rub with a dish sponge until the emulsion is removed completely from your image. Run water over the screen to get both sides nice and wet. When your time is up, remove the glass and tranparency. If you have a UV light source, use that to expose the screen to spec on emulsion manufactures sheet. One on top of screen, one on the bottom sanwiching the film against the screen)

Press the transparancy to the screen with the up side of the print to the bottom of the screen.

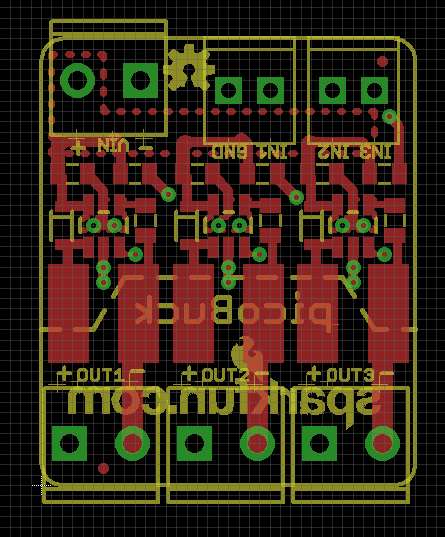

#PCB SILKSCREEN REGISTRATION#

Use some corner or registration marks to assist in lining up. Print the layout exactly as you want it on to transparancy film using BLACK ink only (toner is better). (bug lights are fine) Let it dry to manufactures specs.

Buy a $20 tub of silk screening emultion, (it will last MONTHS) You smear the emulsion on both sides of the screen in a room with a yellow safe light. The thing you cant skimp on is the emulsion. Even panty hose, doubled over, will work. Be sure to use 45 degree cuts to put the four pieces together.

You do not need to use standard "inks" or standard silks.

0 kommentar(er)

0 kommentar(er)